WATCH DESIGN & DEVELOPMENT

Design and Watchmaking

At WMKR, we strongly believe that a great design is the essence of a great watch. That is why our designer in chief personally handpicked and trained each one of our designers on best practices and taught them extensively about watch design.

From turning your concept or idea into a sketch to designing the custom fonts of your watch indexes and marking, we have the skills to give your brand the timepieces design it deserves.

From a Subtle Idea to a Realistic Watch Concept

At the origin of any exceptional watch, you have faint “ingredients”, almost imperceptible, like colors, shapes, lines, curves and an unmistakable ticking sound. WMKR dedicated and accomplished account managers decipher and turn these subtle elements into clear and detailed specifications.

Turn an idea into a wristwatch concept that makes sense in terms of function, design, and technicity, while being economically viable, cannot be improvised. Through horology knowledge, technical expertise and good taste our account managers will conceive, in close collaboration with you, a watch concept as attractive as it is feasible both technically and financially.

WMKR timepiece concepts are comprehensive, and include but are not limited to:

- - Benchmark

- - Mood board

- - Material inspirations

- - Technical specifications

- - Business Plan

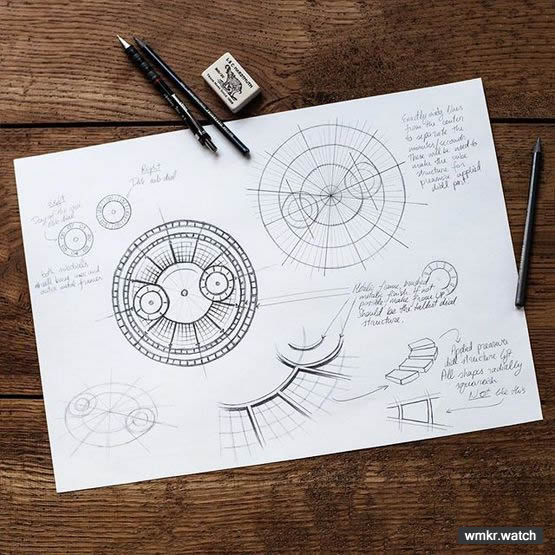

Innovative Wristwatch Design Faithful to Watchmaking Traditions

At WMKR, we are genuinely convinced that a smart and dazzling design is not just relevant but critical in the making of an excellent timepiece. This is the reason why our designer-in-chief personally handpicks and forms each of our creative talents with regular training including watch brands' histories and horology concepts. To our design team, a tachymeter scale is as much about function than aesthetic.

Such a high level of professionalism allows us to offer best-in-class watch designs where every curve on the case, the finish of the dial, the proportion of the indexes, and outline of the hands are all carefully envisioned and drawn without ignoring their elemental function.

Even though we are mastering the digital tools and have built our own custom drawing database of watch components through years of practice, allowing us to move extremely fast and yet propose unique designs, we do not get so easily satisfied, and keep drawing bespoke elements for each and every one of our projects.

Taking the extra time to hand draw a custom font is never wasted time for us. This kind of practice, or we dare to say tradition seldom found nowadays in the watchmaking industry, makes all the difference between a random watch and the timepieces found on our drawing boards.

3D Modeling for Timepieces

Whether it is needed for fine tuning the engineering and design of a timepiece or for marketing use, 3D watch modeling is now crucial in watch manufacturing.

A watch concept always starts with a 2D design. This is the first and essential step where most design details are defined. Then our designer team will work closely with our engineering team to turn the 2D into the3D.

The 3D design modelling is critical as it ensure that the design can realistically be manufactured. The usability, readability of time and overall “feel” of the watch can “virtually” be confirmed in less than a week.

Fast Prototyping of Watches

Even though the 3D modelling and 3D rendering are mature and essential tools, the feel of an object in your hands or in the watch case on your wrist is still relevant.

The prototyping step is something we highly recommend for newcomers in watch business as it resolutely substantiates a watch concept. The usability, readability and overall “feel” of the watch can then undeniably be confirmed.

Wax & CNC Watch Samples

In a watch, the case is the most time-consuming element to make. It usually takes 90 days while other components like dials and hands usually need 30 to 45 days. So, to make a prototype the case can be shaped with 2 techniques of prototyping: wax and CNC.

Wax, as its name indicates, is a 3D printing of the watch. It gives you a good fill of the volumes on the wrist of the watch. It’s time and cost effective. CNC is made by a machine that will shape a piece of metal into the watch case. Then the watch will be manufactured like as usual. It’s the closest to the real thing.

A wax prototyping can be done in a week and a CNC prototyping can be done in a month time.