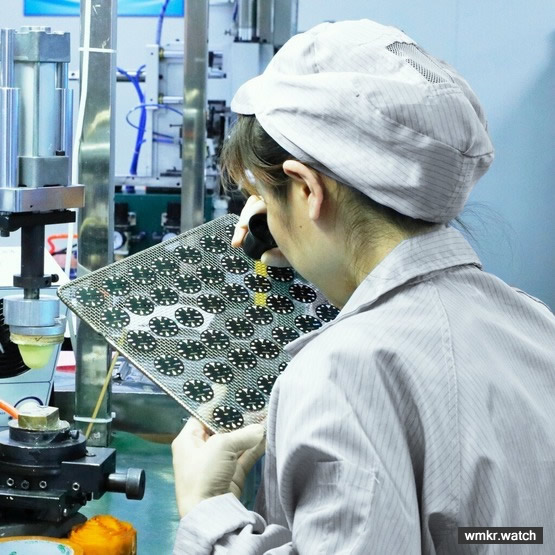

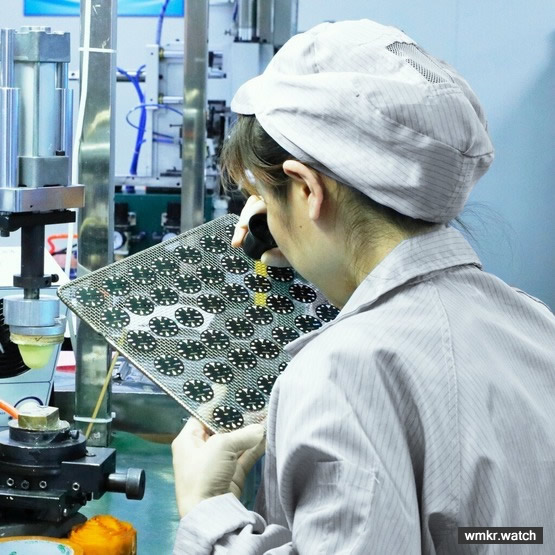

QUALITY CONTROL MANAGEMENT

Quality Watches Starts with the Right Design

We are strong believers that quality does not simply reside in the Final Quality Check nor in the price tag. Quality watches start from the design board to the components sourcing and then on attention to details at every steps of the manufacturing.

Our trained designers and R&D engineers along with our seasoned procurement and assembly teams take quality minded actions long before our QC team enters in action. Our quality team ultimately ensure that quality is delivered.

Quality Control Management

To supply quality watches in low or varying volumes, WMKR is using Quick Response Manufacturing to complement or as an alternative to Six Sigma and Lean Manufacturing strategies. In short, this manufacturing strategy allows us to shorten lead times to achieve top quality while reducing cost and eliminate non-value-added waste within our production system.

We found this manufacturing strategy for watches more efficient to ensure quality and deliverability than the outdated Total Quality Management or TQM still in use in the watch industry.

Lab Testing and Compliance for Watches

From working with our global clients, we know how strategic it is to have compliance for every market. We are aware of the main regulation needed and make sure at every step from design to components procurement that the watches we assemble are compliant from the parts to the packaging.

For instance, to ensure consumer safety and protect our client’s brand and business all our quartz watches delivered to Europe are RoHS Compliant.